A Northwest Alberta producer thought they were not seeing much sand in their Desanders and as such was considering removing the Desanders from their wells in an active completions area. SDI worked with the client to install the SDI Sand Sentry system to measure sand production on these wells as well as some nearby fracked wells to see if and where sand was still an issue. The producer using the data provided by the SDI Sand Sentry system discovered that though the wells produced little sand most of the time there was still significant sand production from slugs and still a need for ongoing Desanding services.

HIGHLIGHTS

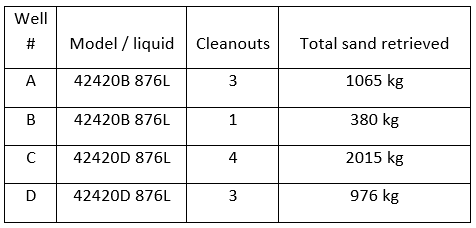

•4 wells were monitored with Sand Sentry over a 10+ month period

•Sand Sentry measured large slugs of sand on wells thought to produce no sand

•Neighboring well data was researched for sand production comparison data

•$30,000 saved in operational downtime and hardware

“If the Sand Sentry wasn’t in place, we would have had thousands of dollars in disruptions and the wells would have went down.” – Representative for the NW Alberta Producer

A Northwest Alberta producer thought they were not seeing much sand in their Desanders and as such was considering removing the Desanders from their wells in an active

completions area. SDI representatives offered 2 solutions:

1. Monitor each well with the SDI Sand Sentry system and chart the changes over the next months.

2. Monitor the amount of frack communication with the wells that the Sand Sentry system was installed on as neighboring wells were being fracked.

Originally the Sand Sentry system was only installed on the one well out of the 4 that was

predicted to produce the most sand. The producer applied the system to the remaining three wells on the pad when more sand began to flow to the surface than was expected. Once the Sand Sentry System was in place on all four wells, SDI was able to help the producer track the sand as it was produced to surface in irregular slugs that originally made the production

impossible to quantify without the SDI Sand Sentry.

The producer was able to prevent significant surface equipment damage on all of the wells. One specific well produced no sand to the surface for the first 90 days of production then unexpectedly experienced frack communication from a neighboring well and started making sand at a very high rate. The Sand Sentry System caught the unexpected sand, stopped in the Desander, and was able to trigger a high level alarm alerting SDI and the producer allowing the producer to take steps to prevent damage to the surface equipment.

The Sand Sentry is perhaps the most imitated piece of technology in the sand control industry, Why? Because it works. As the pioneer of this technology, Specialized Desanders has spent 15 years perfecting this technology in various fields across the world. It allows operators the ability to track, evaluate & optimize their flowback procedures, as well as schedule their cleanouts to minimize disposal costs on produced sand and fluids.

Other technology promises these abilities but simply cannot deliver the same accuracy.

Sick of blowing down competitor vessels & washing out control valves multiple times per week because they cannot detect the amount of sand they have captured?

There is a better way, the Specialized Desanders Sand Sentry System.

20-SDI-Case Study-Sand Sentry Saves Thousands